Automatic double side sticker labeling machine price

Automatic double side sticker labeling machine price

-Suitable for different labels size

-Flexible for different size bottles

-Touch screen & PLC controlled

-Suitable for round and square bottles

- Usage: single and double side labeling

Product introduction

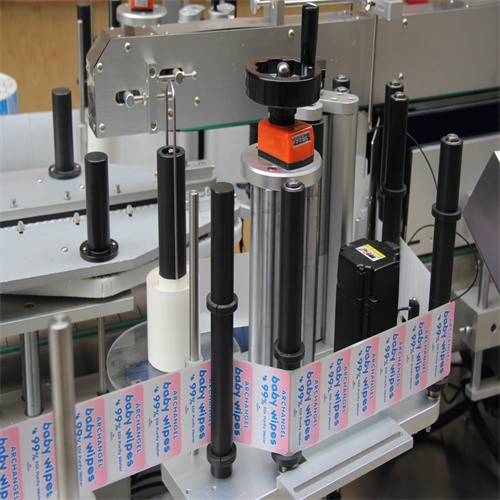

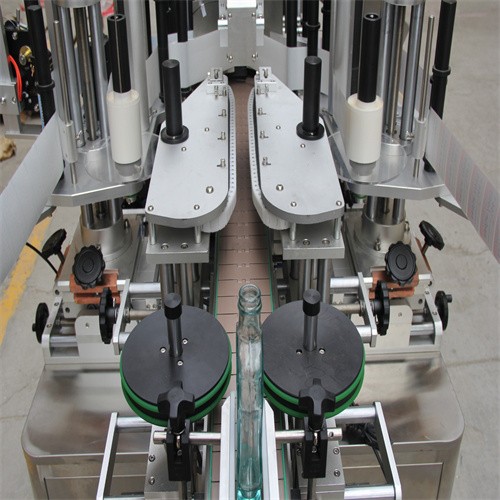

Automatic double side sticker labeling machine is used for one-sided and two-sided labeling of flat bottles, round bottles and square bottles, such as shampoo flat bottles, lubricating oil flat bottles, hand sanitizer round bottles and other two-sided labeling. Both sides are pasted at the same time, and the double labeling improves production efficiency. It is widely used in daily chemical, cosmetic, petrochemical, pharmaceutical and other industries. It can be equipped with code printer or inkjet printer to the sticker head, which can print the production date, batch number, inkjet barcode and other information on the label. It can be equipped with an inkjet printer to the conveyor belt to print the production date, batch number, bar code and other information on the product before or after labeling.

Technical Parameters

Equipment power supply | 220V 50/60Hz |

Power | 3.5KW |

Bottle width | 20-120mm |

Label length | 20-200mm |

Label height | 20-150mm |

Labeling error | ±1mm |

Labeling speed | 20-100pcs/min |

Inside diameter of label roll | 76mm |

Maximum outer diameter of label roll | 350mm |

Unit weigh | 460k |

Overall dimension | 280*195*180cm |

Vdvantage of Automatic double side sticker labeling machine

1.Powerful function, one machine can realize single-sided and double-sided labeling of four products (round bottle, flat bottle, square bottle, special-shaped bottle).

2.It adopts a double-sided rigid plastic synchronous guide chain to automatically ensure the neutrality of the bottle. It has low requirements for workers to put the bottle and dock the bottle into the assembly line, which greatly reduces the difficulty of workers' operation or assembly line docking. It can be produced by a single machine or by assembly line.

3.Configure the spring pressing mechanism to ensure the smooth transportation of products and effectively eliminate the error of bottle height.

4.It is equipped with an automatic bottle separation mechanism, which automatically separates the spacing before bottle guiding to ensure the stability of subsequent bottle guiding, conveying and labeling

5.The double labeling mechanism is configured to ensure the labeling accuracy for the first time, and the secondary extrusion labeling can effectively eliminate bubbles and ensure the tightness of the label at the head and tail.

6.Intelligent control, automatic photoelectric tracking, with no labeling, no labeling automatic correction and label automatic detection functions, to avoid wasting labels and missing labels.

7.The main materials of the equipment are stainless steel and wear-resistant aluminum alloy, which comply with GMP production specifications. The overall structure is firm and beautiful.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Jackson Huang

Phone: 15799924005

E-mail: info@xyzmachinery.com

Whatsapp:0086-15799924005

Add: Wenzhou Zhejiang